Oil Free Air Compressor Working Principle PDF: Understanding the Technology

Introduction

Oil-free air compressors have become increasingly popular in various industries due to their ability to provide clean, oil-free compressed air essential for sensitive applications. This article explores the working principles of Oil free air compressor working principle PDF discusses the advantages of using them, and provides insights into downloadable PDF resources that offer further information and guidelines.

Working Principle of Oil Free Air Compressors

Oil-free air compressors operate on advanced engineering principles designed to eliminate the use of lubricating oil in the compression process. This section will detail the various technologies employed, such as scroll compressors, piston ring designs, and water injection methods, highlighting how each method achieves efficient compression while ensuring air purity.

Advantages of Oil Free Air Compressors

1. Clean and Contaminant-Free Air: Oil-free air compressors excel in delivering air that is free from oil contaminants, making them essential in industries where air quality is critical, such as pharmaceutical manufacturing and food processing.

2. Reduced Maintenance Requirements: By eliminating the need for oil changes and associated maintenance tasks, oil-free compressors simplify maintenance routines, reduce operational downtime, and lower overall maintenance costs.

3. Environmental Sustainability: Oil-free air compressors contribute to environmental sustainability by eliminating oil disposal issues and reducing carbon emissions associated with oil use, aligning with green manufacturing practices.

Read also: Why Beauty Machines are Your Ultimate Beauty Solution

4. Suitable for Sensitive Applications: Due to their ability to deliver clean, oil-free air, these compressors are ideal for applications requiring high air quality standards, including medical air systems and semiconductor manufacturing.

Downloadable PDF Resources

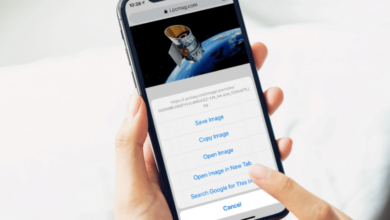

This section will provide links or references to downloadable PDF resources that offer detailed information on the working principles, maintenance guidelines, troubleshooting tips, and case studies related to oil-free air compressors. These resources serve as valuable tools for engineers, technicians, and facilities managers looking to understand and optimize the performance of oil-free compressor systems.

Applications Across Industries

Oil-free air compressors find widespread applications across diverse industries and specialized environments, including healthcare facilities, cleanroom environments, laboratories, and food production facilities. This section will provide case studies and examples highlighting their usage and benefits in each sector.

Comparative Analysis: Oil-Free vs. Oil-Lubricated Compressors

A comparative analysis will be conducted to highlight the differences between oil-free and oil-lubricated compressors in terms of performance, maintenance requirements, lifecycle costs, and environmental impact. This analysis will assist readers in making informed decisions based on their specific operational needs and requirements.

Future Trends and Innovations

The article will conclude with a discussion on future trends and innovations in oil-free air compressor technology. This includes advancements in materials, design improvements for enhanced efficiency and reliability, and the integration of smart technologies for remote monitoring and predictive maintenance.

Conclusion

Oil-free air compressors represent a significant advancement in air compression technology, offering unparalleled benefits in terms of air purity, operational efficiency, and environmental sustainability. By understanding their working principles and leveraging downloadable PDF resources, industries can maximize the benefits of oil-free air compressor systems while ensuring compliance with regulatory standards and operational excellence.