The Versatility and Benefits of Foam Protective Packaging

Introduction

Foam protective packaging is an essential component in the logistics and transportation industries, ensuring the safe arrival of products from one destination to another. This type of packaging is designed to provide maximum protection by absorbing shocks and distributing impact forces evenly. Foam protective packaging is widely used in various sectors, including electronics, automotive, and healthcare, due to its exceptional cushioning properties and versatility. In this article, we will delve into the benefits, applications, and features of foam protective packaging, with a particular focus on polyethylene foam packaging.

Understanding Polyethylene Foam Packaging

Polyethylene foam packaging is a popular choice within the realm of foam protective packaging. It is manufactured from polyethylene, a durable and lightweight polymer, making it ideal for protecting a wide range of products. Polyethylene foam is a cross-linked foam known for its repeatable performance and durability, especially in multi-trip packaging and factory transit applications.

Key Features of Polyethylene Foam Packaging

- Durability and Reusability: Polyethylene foam is highly durable and suitable for reuse in multi-trip packaging scenarios. This makes it an economical choice for businesses that require dependable protection for their products over multiple shipments.

- Impact Absorption: The foam structure consists of numerous cells that act as tiny shock absorbers. This unique feature allows polyethylene foam packaging to absorb and distribute impact forces effectively, reducing the risk of damage during transportation.

- Moisture and Chemical Resistance: Polyethylene foam is resistant to moisture, chemicals, and temperature fluctuations. This makes it an excellent choice for packaging products that are sensitive to these factors, such as electronics and medical devices.

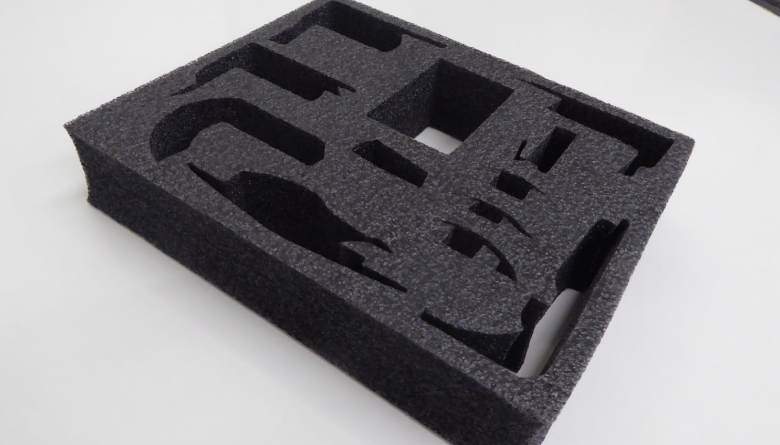

- Customizability: Polyethylene foam packaging can be tailored to meet specific product requirements. Bespoke designs or standard packaging solutions are available to optimize performance and cost, ensuring that goods arrive safely.

Versatile and Innovative Solution

Polyethylene foam packaging stands out as a versatile and innovative solution in the protective packaging industry. Its adaptability and effectiveness make it suitable for various applications, ensuring the safe transit of fragile and delicate items.

Applications of Polyethylene Foam Packaging

- Electronics: The electronics industry relies heavily on polyethylene foam packaging to safeguard devices such as smartphones, laptops, and computer components. The foam’s cushioning properties protect these sensitive items from shocks and vibrations during shipping.

- Automotive: In the automotive sector, polyethylene foam packaging is used to protect parts and components from damage during transit. Its durability ensures that even heavy and complex items are securely transported.

- Healthcare: Medical devices and equipment require careful handling to prevent damage. Polyethylene foam packaging provides a protective barrier against impact and environmental factors, ensuring that these critical items reach their destination safely.

Specialized Foams

Several specialized foams fall under the umbrella of polyethylene foam packaging. These include Nomafoam, Plaztazote, and Zotefoam. These foams are often used with specific tooling to create custom solutions for various industries. Additionally, polyethylene foams are available in different colors such as black, white, blue, and anti-static pink, catering to diverse packaging needs.

The Complete Packaging Service

Choosing polyethylene foam packaging from a reliable supplier offers several advantages. A complete packaging service can simplify the design process and ensure that all packaging components are compatible and optimized for performance.

Benefits of a Complete Service

- Single Source Supply: Working with a single supplier for both boxes and polyethylene foam fitments simplifies ordering and reduces paperwork. This streamlined process ensures a quick response to queries and efficient stock management.

- Custom Fitments: Suppliers can match carton strength and internal fitments to provide the best value for money. Custom solutions are designed to meet specific product requirements, ensuring maximum protection.

- Additional Packaging Products: Beyond foam packaging, suppliers often provide other packaging products such as tape and bubble wrap. This comprehensive approach ensures that all necessary packaging materials are available from one source.

Benefits of Foam Protective Packaging

Foam protective packaging offers numerous benefits that make it an indispensable choice for protecting goods during transit.

Key Benefits

- Enhanced Protection: Foam protective packaging provides superior cushioning and impact absorption, reducing the risk of damage to fragile items.

- Cost-Effective: Despite being more expensive than some alternatives, such as polystyrene, polyethylene foam packaging’s durability and reusability make it a cost-effective option in the long run.

- Versatility: The versatility of foam protective packaging allows it to be used across various industries and applications, from electronics to automotive and healthcare.

- Environmental Resistance: Resistance to moisture, chemicals, and temperature fluctuations ensures that products remain protected under different environmental conditions.

Conclusion

In conclusion, foam protective packaging, particularly polyethylene foam packaging, is a vital solution for ensuring the safe transit of products across various industries. Its exceptional cushioning properties, durability, and resistance to environmental factors make it an ideal choice for protecting delicate and valuable items. By opting for polyethylene foam packaging, businesses can enhance their product protection strategies, minimize damage risks, and ultimately ensure customer satisfaction. The versatility and effectiveness of foam protective packaging underscore its importance in modern logistics and packaging solutions.