Ten Types of Thermal Interface Material

Proper heat management is crucial for devices ranging from smartphones to supercomputers. Thermal Interface Material (TIM) is vital for efficiently transferring heat away from components, maintaining performance, and extending lifespan. This guide examines 10 types of TIMs, detailing their distinct properties and ideal applications. Whether you’re an engineer or a DIY enthusiast, you’ll find valuable insights to help you choose the right TIM for your needs.

Why TIMs Are Important in Electronics

Thermal interface materials (TIMs) help keep electronic devices cool by transferring heat away from key components like processors and graphics cards. As these components work harder and get faster, they generate more heat. Without proper cooling, this can lead to slower performance (thermal throttling) or even hardware damage.

TIMs prevent overheating, ensuring devices run efficiently and last longer. With today’s smaller, more powerful electronics, good heat management is more important than ever. Choosing the right TIM improves performance, reduces risks, and increases reliability, making it a crucial decision for engineers and device designers.

Types of TIM

Thermal Interface Materials come in different forms, each suited for specific applications and performance needs. Understanding these types can help you choose the right one.

1. Thermal Grease: Enhancing Heat Transfer

Thermal grease, also called thermal paste, helps electronic components stay cool by improving heat transfer. It fills tiny gaps between a processor (like a CPU or GPU) and a heatsink, ensuring better contact and more efficient cooling.

Made from materials like silicone and metal oxides, thermal grease remains stable at different temperatures, making it ideal for high-performance devices that generate a lot of heat.

Applying it is simple—just spread a thin layer on the processor before attaching the heatsink. This small step can make a big difference in cooling efficiency and help extend the lifespan of your device.

One great advantage of thermal grease is that it can be cleaned off and reapplied when needed, making it a reusable and practical choice for computer maintenance and repairs.

2. Phase Change Materials: Smart Heat Management

Phase Change Materials (PCMs) are special substances that control heat by changing from solid to liquid and back again. They absorb heat when they melt and release it when they solidify, helping keep electronic devices at a stable temperature.

When a device gets hot, the PCM melts, soaking up excess heat. As the temperature drops, it hardens again, releasing stored energy. This process happens naturally, without needing extra power, making PCMs an excellent option for passive cooling.

Different types of PCMs are designed for various applications, from high-performance computers to everyday consumer electronics. Their ability to manage heat efficiently and reliably makes them a growing favorite among engineers and designers.

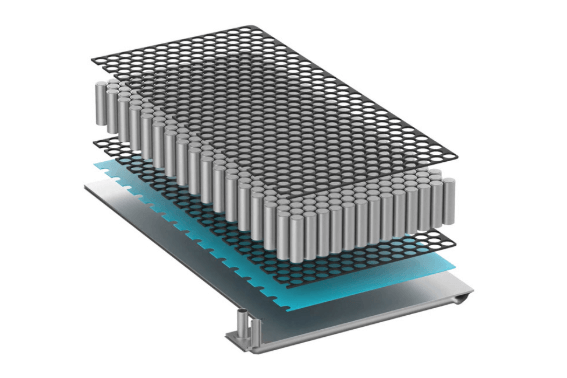

3. Gap Fillers: Flexible Solutions for Heat Management

Gap fillers play an essential role in keeping electronic devices cool. They fill tiny spaces and imperfections between components, improving contact and ensuring efficient heat transfer. These materials are designed to be both highly thermally conductive and flexible, allowing them to conform to uneven surfaces. This adaptability makes them effective under varying pressure conditions.

Typically made from silicone or other polymer-based compounds, gap fillers provide strong insulation while still transferring heat efficiently.

A major benefit is their ease of application. They can be quickly dispensed onto components, simplifying the assembly process without reducing performance.

Gap fillers are especially valuable in compact devices where space is limited, helping maintain safe operating temperatures in everything from consumer gadgets to industrial equipment.

4. Graphite Films: Advanced Heat Dissipation

Graphite films are becoming a go-to choice for managing heat in electronics. Their thin, flexible layers of graphite offer outstanding thermal conductivity, efficiently drawing heat away from critical components.

One of their biggest advantages is their adaptability. Graphite films can conform to various surfaces, ensuring a tight fit and reducing air gaps that might limit heat dissipation.

They are also lightweight and easy to apply, requiring no curing or complex installation. This makes them a practical alternative to traditional thermal materials.

Additionally, graphite films remain stable even at high temperatures, making them ideal for demanding environments. As electronics continue to advance, graphite films are set to play an even bigger role in thermal management.

5. Liquid Metals (Simplified Explanation)

Liquid metals are special materials used for cooling electronics. Made from gallium or indium alloys, they stay in a liquid state at room temperature, allowing them to fill tiny gaps between surfaces. This improves heat transfer and keeps devices from overheating.

They are much better at conducting heat than traditional thermal pastes. However, they must be handled carefully, as they can corrode aluminum and may leak if not applied correctly. Despite these challenges, liquid metals are becoming more popular for high-performance cooling solutions.

6. Carbon Nanotubes (Simplified Explanation)

Carbon nanotubes are tiny, tube-shaped materials that are excellent at conducting heat. They help electronic devices stay cool by transferring heat efficiently.

They are lightweight, flexible, and durable, making them ideal for modern electronics. Because they don’t wear out easily, they provide long-lasting performance. Research is ongoing to explore even more ways to use carbon nanotubes in advanced cooling technologies.

7. Thermally Conductive Adhesives (Simplified Explanation)

Thermally conductive adhesives help both bond electronic components and transfer heat efficiently. They contain metal fillers like silver or aluminum to improve heat conduction while maintaining strong adhesion.

These adhesives are ideal for assembling delicate electronics, as they provide stability and cooling in compact spaces. Different types are available—some cure quickly, while others remain flexible after hardening.

Beyond electronics, they are also used in the automotive and aerospace industries, proving their value in applications requiring both heat management and structural support.

8. Ceramic-Based TIMs (Simplified Explanation)

Ceramic-based thermal interface materials (TIMs) are great for managing heat in high-temperature environments. Made with materials like aluminum oxide or silicon carbide, they efficiently transfer heat while remaining stable over time.

A key benefit is their electrical insulation, which protects sensitive electronics from electrical interference.

However, they can be more brittle than other options, requiring careful handling during installation.

As technology advances, improved ceramic TIMs continue to be developed, making them a strong choice for industries that need reliable and long-lasting thermal solutions.

9. Metal-Based TIMs (Simplified Explanation)

Metal-based thermal interface materials (TIMs) are highly effective at transferring heat, often outperforming polymer-based alternatives. They are commonly made from materials like silver or copper, making them ideal for high-performance applications.

These TIMs efficiently dissipate heat from electronic components, helping to prevent overheating. However, they can be rigid and require careful application to avoid stress from thermal expansion. They also tend to be more expensive than other TIM options.

Despite these challenges, engineers prefer metal-based TIMs for their superior heat management, which improves the reliability and lifespan of electronic devices.

Read also: Huawei’s Data Center Facility: The Ultimate Tech Infrastructure

Factors to Consider When Choosing the Right TIM

When selecting a TIM for your electronic devices, several important factors need to be considered to ensure effective heat management:

- Thermal Conductivity – TIMs vary in their ability to transfer heat. High-performance electronics require materials with excellent thermal conductivity to prevent overheating.

- Material Type & Properties – TIMs come in different forms, such as liquid pastes, pads, and adhesive tapes. Liquids like thermal grease spread easily, while pads provide durability and ease of use. The material should also effectively fill gaps between surfaces to improve heat transfer.

- Operating Temperature Range – Some TIMs perform well at standard temperatures but degrade under extreme heat. Choose a material that can withstand the conditions of your device without losing effectiveness.

- Durability & Longevity – A TIM should be stable over time, resisting drying out, cracking, or breaking down due to prolonged use or environmental factors.

- Adhesion Strength – Some TIMs also act as adhesives, securing components while transferring heat. For a strong bond, adhesive-based TIMs are better than regular thermal paste.

- Cost vs. Performance – Higher-end TIMs typically offer better performance, but it’s essential to balance cost with thermal efficiency requirements.

By considering these factors, you can select the best TIM for optimal cooling, enhanced performance, and extended component lifespan.